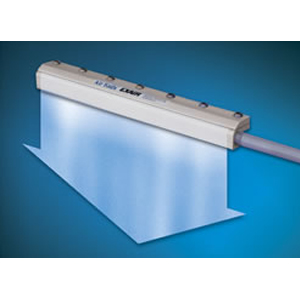

EXAIR’s Super Air Knife is the latest generation of air knife that dramatically reduces compressed air usage and noise when compared to other blowoffs. The Super Air Knife offers a more efficient way to clean, dry or cool parts, webs or conveyors. It delivers a uniform sheet of laminar airflow across the entire length with hard-hitting force.

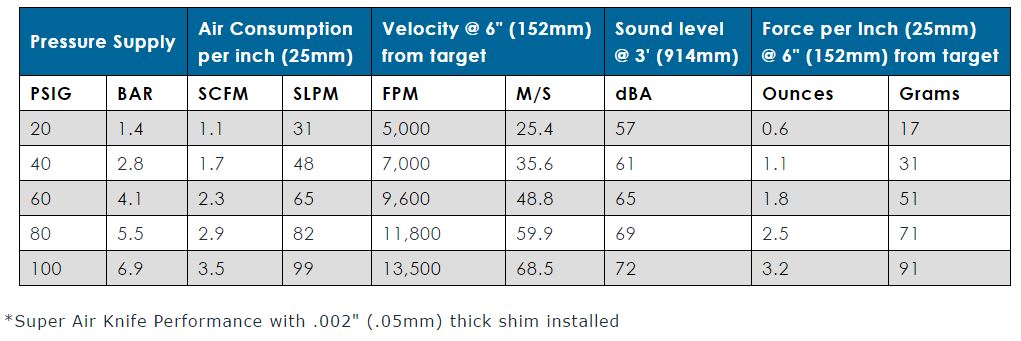

Noisy blowoffs become a whisper when replaced with the compact Super Air Knife. Even at high pressures of 80 PSIG (5.5 BAR), the sound level is surprisingly quiet at 69 dBA for most applications! Amplification ratios (entrained air to compressed air) of 40:1 are produced. The Super Air Knife meets OSHA dead-ended pressure and noise requirements.