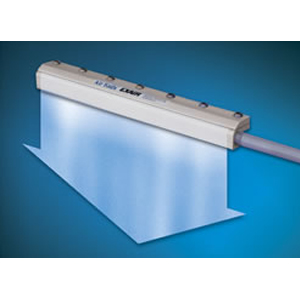

A quiet, energy efficient way to clean, dry or cool parts, webs or conveyors. The Standard Air Knife utilizes the coanda effect (wall attachment of a high velocity fluid) to create air motion in its surroundings. Using a small amount of compressed air as a power source, the Standard Air Knife pulls in large volumes of surrounding air to produce a high flow, high velocity curtain of air for blowoff.

Amplification ratios (entrained air to compressed air) of 30:1 are achieved with the Standard Air Knife, compared to 3:1 for drilled or slotted pipe. Air savings of 40% to 90% are possible when replacing these “homemade” blowoff devices. Pay-back is normally measured in weeks, not months or years. The Standard Air Knife dramatically reduces “wind shear” by gradually introducing the entrained air to the ejected compressed air. Noise level is typically cut in half. The result is a high velocity, high volume sheet of air with reduced noise level and air consumption.

Drilled pipe or open jets, by contrast, provide minimal air amplification. They also produce unacceptably high noise levels as the compressed air shears into the still air.