Applications

- Tool sharpening

- Drill & cutter grinding

- Routing

- Plunge and form grinding

- Milling

- Surface grinding

- Drilling

- Tire grinding

- Band sawing

- Plastic machining

Advantages

- Improves production rates

- Prevents burning

- Extends tool life – reduces breakage

- Improves tolerance control

- Prevents smearing of metal and plastics

- Finished part is dry

- Eliminates wheel loading

- Low cost – no coolant or electricity

- Compact, lightweight, portable

- No moving parts – maintenance free

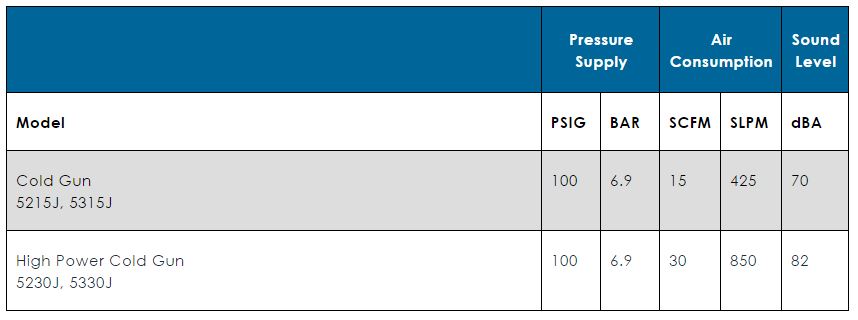

- Quiet (now only 70 dBA!)

Tool Grinding

Cold air eliminates heat cracking of carbide and tool edge burning during grinding and sharpening operations. Increased tool life between regrinds is the result.

Milling & Drilling

Fly cutters up to 460mm in diameter have been cooled with the Cold Gun. Dissipating heat with cold air extends tool life, increases speeds and feeds, and improves finishes.

Chill Roll

Cooling a roll with 20°F (-7°C) air keeps the material on the surface from bunching up, jamming or tearing. The metal surface transfers the cold temperature to the product.

Laser Cutting

Cold air cools a laser cut part so it can be handled seconds later. The High Power Cold Gun has twice the cooling capacity of the standard Cold Gun, cooling the part in less time.