EXAIR Vortex Tubes are constructed of stainless steel. The wear resistance of stainless steel, as well as its resistance to corrosion and oxidation, assures that EXAIR Vortex Tubes will provide years of reliable, maintenance-free operation.

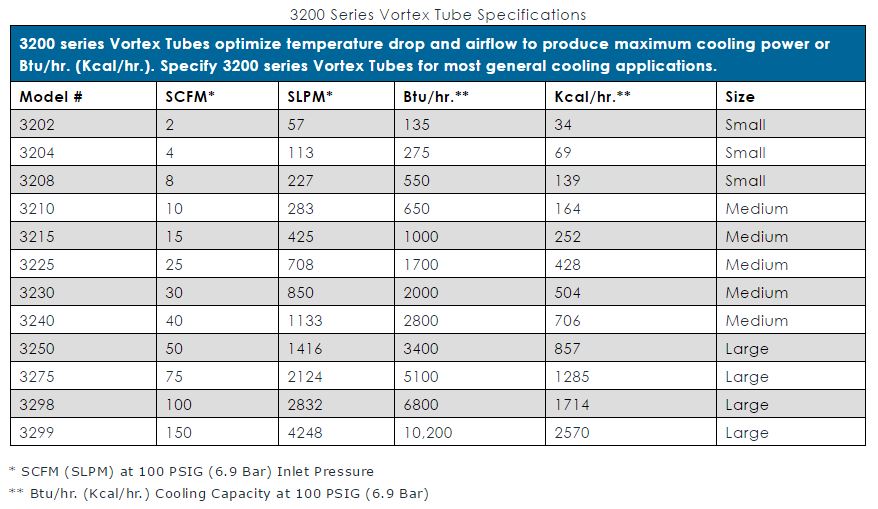

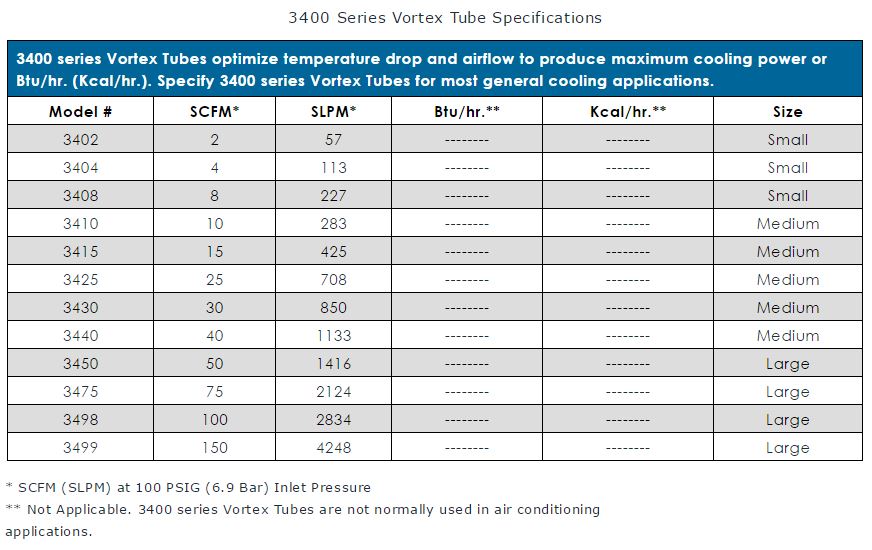

EXAIR Vortex Tubes are available in three sizes. Each size can produce a number of flow rates, as determined by a small internal part called a generator. If Btu/hr. (Kcal/hr.) requirements, or flow and temperature requirements are known, simply select the appropriate vortex tube according to the specification information shown below or the performance charts. Keep in mind that the vortex generators are interchangeable. If, for example, a Model 3215 Vortex Tube does not provide sufficient cooling, you need only change generators within the vortex tube to upgrade the flow rate from 15 to 25, 30 or 40 SCFM (425 to 708, 850 or 1133 SLPM).