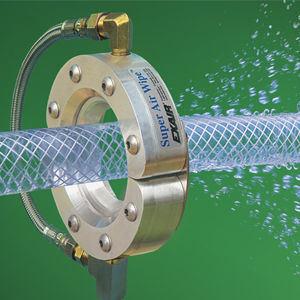

Prior to the introduction of the Super Air Wipe, the only way to blowoff, dry, clean and cool cylindrical, round, or extruded surfaces was to use a ring of air nozzles. The high air consumption and noise levels of the nozzles along with inconsistent air velocity often delivered poor results.

The Super Air Wipe provides a high volume, high velocity airflow that is uniformly ejected from the 360° of its inner diameter. The airstream attaches itself to the material running through it to effectively wipe, clean or dry surfaces. Velocity can be varied from a “blast” to a “breeze”. Air consumption and noise are low.

Applications

- Drying after wash, cleaning, plating or coating

- Blowoff dust and contaminants

- Cool hot extruded shapes

- Uniformly wipe surfaces

- Dry extruded profiles, rod and medical tubing

- Eliminate solution carryover – no cross contamination

- Blow excess water from automotive door gaskets

- Remove excess coatings, water and oil

- Dry tube, hose, wire, fiber optics

- Minimize solution loss due to dragout

- Clean paint gun tips

- Dry screen printed or ink jetted surfaces

- Clean strips and ribbon

Advantages

- Quiet

- Low air consumption

- Uniform airflow across the entire diameter

- No electricity, no moving parts

- Non-contact – no wiper blade

- Variable force and flow

- Lightweight, low profile

- Tapped holes for mounting

- Split design – compact, rugged, easy to install

- Stainless steel hose supplied on sizes up to 4″ (102mm)

- Stainless steel hardware resists corrosion

- Aluminium models for temperatures up to 400°F (204°C)

- Stainless steel models for temperatures up to 800°F (427°C)

- Meets OSHA maximum dead end pressure and noise requirements