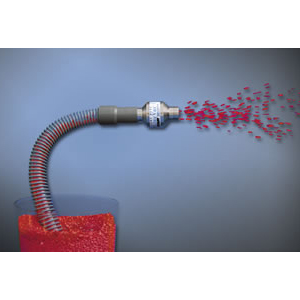

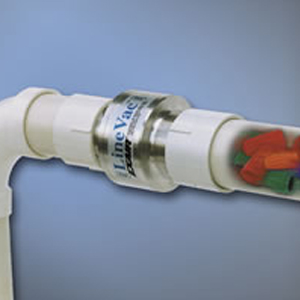

Line Vac conveyors are ideal for moving large volumes of material over long distances. A small amount of compressed air is injected through directed nozzles to produce a vacuum on one end and high output flows on the other, with instantaneous response. The material flow rate is easily controlled with a pressure regulator. An optional bracket permits easy mounting. No moving parts or electricity assures maintenance-free operation.

| Line Vac is a fast, low cost way to convey: | |

|

|

Applications | Advantages |

|

|